The two-phase remodel of the Thunderbird Dining Facility involved the complete reconfiguration of antiquated utilities and serving lines, the introduction of a new menu, the preparation of optimized layouts for seating and serving areas, and the replacement of all lighting, signage, and decor.

All of this was achieved by deploying our five-step DFAC Update Process:

- Survey the Need

- Create Menu & Equipment Layouts

- Envision Interior Concepts

- Prepare Design Layouts

- Commit to an Installation Timeline

Step 1: Survey the Need

Food service staff and base personnel were burdened a substandard dining environment in which to prepare and consume food: utilities were outdated and jury-rigged, food presentation and menu options were unappealing, and the furnishings institutional. Additionally, wait times and serving hours were not conducive to performing work duties on a tight schedule.

Our interviews with Food Program Managers revealed a number of additional challenges:

- Safety considerations with exposed cords and plugs that were trip hazards

- Moving customers more quickly through the serving area

- Not having enough versatility in equipment support

Underscoring our work was a mandate to provide a DFAC in which healthy meals could be served in a timely fashion, thereby ensuring repeat visits and the reduction of unhealthy food choices (as personnel are known to frequent fast-food options for the sake of expediency, familiarity, and taste).

The bottom line? Increase utilization.

We then measured and documented the front- and back-of-house, noting the location of all mechanical, electrical, plumbing, and structure systems that could potentially impact design decisions.

Step 2: Create Menu & Equipment Layouts

Any DFAC update must include the modernization of its menu offering by providing healthier food choices that adhere to the Go Green Initiative, a joint service nutrition plan that deploys nutrition improvements that achieve and maintain optimum health and the highest level of fitness and performance.

This policy was realized at Fort Huachuca through menu choices that include:

- Showcasing more Green Level high-performance food.

- Increasing menu rotation to promote healthier choices.

Step 3: Envision Interior Concepts

Yet, despite the urgencies presented by the condition of the physical plant, the question on most minds is usually “what will it look like?”. And that’s where our designers excel: in creating dining spaces with uncharacteristic visual appeal, while keeping in mind the practical need to specify durable and timeless finishes, fixtures, and equipment.

This “look and feel” was presented through a series of life-like three-dimensional computer renderings that depicted legible signage, a historical timeline, new LCD menu systems, and interior finishes which had to match existing floor and wall treatments.

Step 4: Prepare Design Layouts

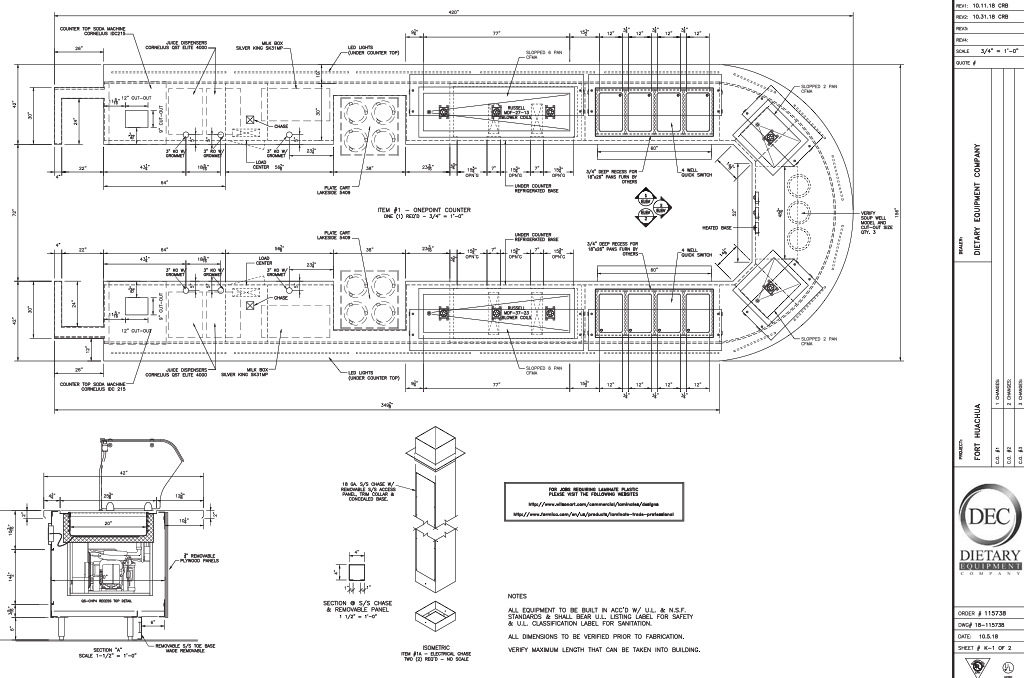

Ours is an iterative design process consisting of site sketches which are then translated to dimensionally accurate CAD drawings. These were reviewed by the Food Program Manager, revised, then resubmitted for final approval along with an attached estimate and schedule.

All major systems from beverage, water and gas lines, to seating, to electrical service and lighting were delineated, scheduled and carefully coordinated to streamline the manufacturing process and to minimize change orders and construction delays.

Step 5: Commit to an Installation Timeline

DFAC Update provided project management services from start to finish, with installation and DPW. All furnishings, fixtures, and equipment were delivered, assembled, and installed over a three-day weekend. Of particular note was the connection of the utility raceway into a single point.

Our view is that the job isn’t done until is it done. This means our punch list will be completed to your satisfaction.